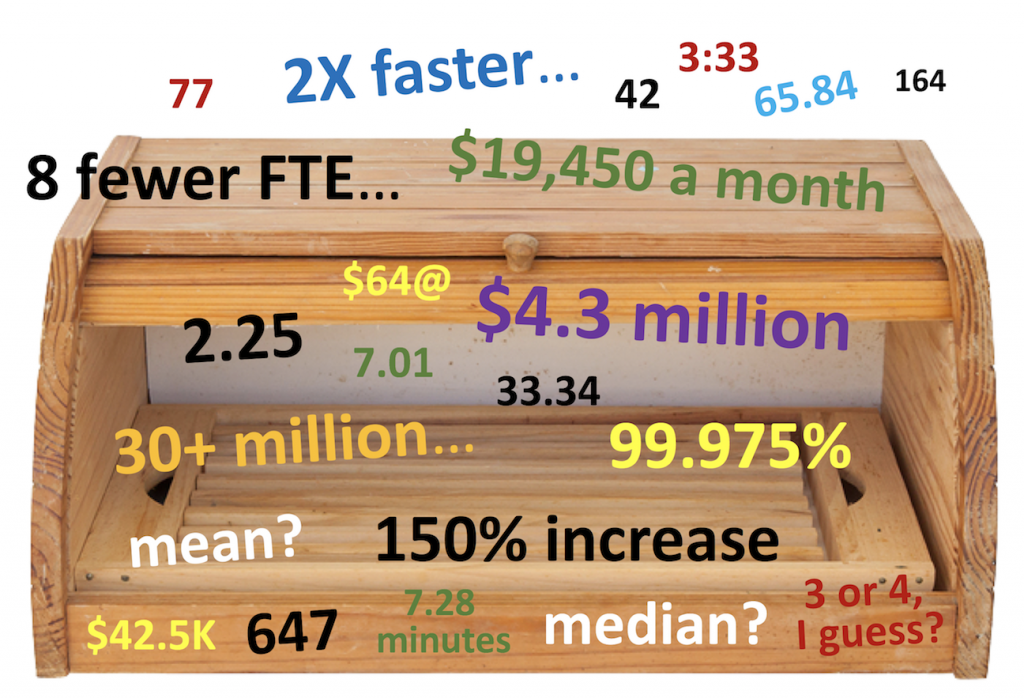

Is it bigger than a breadbox?

Have you ever interviewed a someone who says they have “no metrics” for your case study?

Perhaps your source never had to justify their purchase, so they didn’t keep any formal metrics.

That means they have no numbers to show how much your offering helped with their business problems… and no numbers you can use in your case study.

Whether you’re a writer or a marketing manager, that’s not what you want to hear. Fortunately, there’s something you can do about it.

When this happens to me, I often start a line of questioning I call, “Is it bigger than a breadbox?”

This question was first posed by Steve Allen on the American game show “What’s My Line?”

It’s a classic from “20 Questions” too. And it’s handy any time you have to interview someone who says they have “no metrics.”

Knowing that something is bigger or smaller than something else helps narrow the field of possibilities. This line of questioning leads your source through some back-of-the-envelope calculations.

This article shows a typical example of playing the game and the metrics you can derive from it.

And there’s a bonus tip on how to convert from one metric to another to make your results more meaningful to your audience.

A typical conversation with a source

Perhaps our discussion starts like this.

My source says, “We’re saving a lot of time now!”

So I ask, “How much time, would you say?”

When they say they don’t know, and they never kept track, I ask, “Well, how many people work in your warehouse?”

They say 20 on days, 15 on nights.

“So that’s 35 full-time people in the warehouse?”

“Yes,” they confirm.

“And was it always that number?”

“Oh no, before we got the new system, we had more. We’ve been able to put some people on days, which they prefer. And we reallocated some people to other jobs. And we let go a few poor performers.”

This is when you help guide their reasoning.

“Okay, so how many people did you re-allocate? And how many did you let go?”

“I think 4 we re-allocated, and 3 we let go.”

“So you need 7 fewer people in the warehouse? And you still handle the same number of orders?”

“Oh no, we’re doing more orders with fewer people. Let me check…”

They take a minute to look up a report on their screen. “Yeah, we’re doing about 20% more orders with seven fewer people.”

“Wow, that’s great!” I say.

“Yeah, as I told you, we’re pretty happy about that.”

So there’s a first metric you can use. But you don’t have to stop there.

Playing hi-low to get another metric

“Well, let’s see if we can develop that a little. So, what’s the typical wage for a warehouse person there?”

“Well, that varies all over the map. They can make bonuses. And we pay a premium for working nights.”

When your source says there’s no “average” value, because the numbers fall over such a vast range, you can use a variation of the “breadbox” question.

You can call this version “Hi-Low.” Ask your source for the highest and lowest values, and then ask what would be about the middle.

Here’s how it works.

“Well, if I asked for the absolute lowest and the highest possible, what would the range be?”

“Well, I’d say a day guy who really doesn’t push it very hard, he’s making $35,000. And a real go-getter at night who picks and packs faster than anybody, he could reach close to $50K with all his bonuses.”

“Okay, so the range is $35K to $50K. That totals $85 divided by 2, let’s see, umm… that $42.5K average.

“So if we say your average warehouse worker makes $40K, does that sound about right?”

Your source thinks a bit.

“Hmmm… well, most guys push it on this job. They love the bonuses, and they come in on Saturdays if we need.

“I’d say we can stick to $42.5K average.”

“Great, thanks. So we already figured out you have 7 fewer people in the warehouse. At $42.5K each, that’s a savings of what… $297,500. Wow, that’s like $300K a year!”

“Gee, I never looked at it like that before. That system will pay for itself within a year!”

Don’t forget overhead

But the game isn’t over yet.

Don’t forget the overhead for every worker: things like payroll taxes, insurance, the cost of utilities like power and air conditioning. Ask about all that too.

“And there’s got to be an overhead factor for every worker, right?” I ask. “To cover all the payroll taxes, benefits, insurance, utilities, and all that kind of stuff?”

“Sure. We use a conservative number, so it’s not actually fully loaded,” they say. “Like at the warehouse, we don’t have to pay for planting flowers or buying desks or the stuff they need for the office.”

“That sounds sensible. So what number do you use?”

“We use $7,500 per worker per year. Just to keep it simple.”

“Ok, so that adds another $7.5K times 7 to our savings, right?”

“Yeah. I’ve got a calculator here,” they offer. Often they want to see the numbers for themselves.

“So that’s another $52,500 in savings. At least.”

“Okay, thanks,” I say. And then we both add it all up.

“So we have savings on labor of $297,500 plus savings on overhead of $52,500 which equals… $350,000 on the button. Wow.”

“That’s over a third of a million dollars!” they chortle. “Wait till I tell my boss!”

Confirming the bottom line

“You’re right, it is! Congratulations!”

“Well, it was the new system that did it. Just like I hoped it would,” they say.

“So can we put in the story that you’re saving $350,000 a year on labor in the warehouse?”

“Sure! And the best thing is, we’re getting more orders out. Another reason for that is we have fewer guys cluttering up the aisles, getting in each other’s way and slowing down the forklifts. So the new system is giving us all kinds of benefits that help the warehouse run faster and smoother.”

So you can see how, in five or 10 minutes of interview time, we went from “no metrics” to an impressive number on labor savings.

Documenting the new metric

After the call, I like to jot down our reasoning in a quick e-mail to my source. This gives us both a record, so we won’t forget where that number came from.

My source often forwards that e-mail to their manager as well. And I send it to my client as backup for that metric.

Bonus tip: Translating one metric to another

You can translate one metric into another that may be more meaningful to the outside world.

Just remember not to stretch the truth.

Your business readers are not gullible. Some of them have MBAs. Some of them work in Finance. They can sniff out shoddy statistics.

How else could you express that $350,000 savings on labor?

Here are three more possibilities.

1. Headcount reduction: Total number of workers

Another way you could express your new metric is to say the warehouse reduced its headcount by 7.

As a percentage, that’s 7 out of the former total of 35 workers, or 20% reduction in labor.

2. Productivity: Number of orders handled per worker

You could take the number of orders divided by 35 warehouse people before the new system. That would show the average number of orders filled per worker: a measure of productivity.

Then take the bigger number of orders handled today divided by only 28 people after the new system.

Compare the two numbers. The new number is bound to be higher than the old.

You can express the comparison as a percentage gain in productivity.

3. Turnaround: Time to fill an order

Ask your source for the total number of hours in a week. If you need to, play hi-low to get the number of hours a typical worker puts in.

Then multiply a week’s worth of hours by 35 workers to find the total number of hours worked before.

Divide that by the average number of orders filled in a week before. You’ll get the average amount of time it used to take to fill an order.

Then you could do similar calculations for 28 workers and the number of orders after the new system arrived.

Compare the two numbers. The new number is bound to be lower than the old.

You can express the difference as a percentage gain in turnaround time.

So there you have it: a handful of powerful metrics from a source who said they had none.

And you can get them all by playing “Is it bigger than a breadbox?” for a few minutes during an interview.

Do you have any tips to share on how to get solid evidence from a source? Please leave a Comment below.

Want to hear whenever there’s a fresh article on this site? Subscribe here to stay in the know on long-form content. From time to time, we’ll also send you word about some great new resource or training. And you can unsubscribe any time.

Great, personable strategy for sussing out useful numbers. Thanks for sharing, Gordon.

Solid article Gordon – Reminds me of something I learned in a course on gathering info in interview for building apps backwards (finding the pain points and quantifying the cost of the biz owner’s problem/value of your solution). We were taught to keep digging, asking the questions about numbers and dollars until we did hit on something quantifiable for the seemingly unquantifiable. And as a side note – bought your terrifically helpful White Paper for Dummies book. Thanks for that! Sara

The $7,500 per worker per year is not an accurate number in any way shape or form. With the exception of SUTA, FUTA, FICA or whatever your state may charge in their payroll taxing structure the indirect overhead you mention remains constant so the savings are less than what your article proposes and if I were a Plant Manager looking at bringing you on I would know and understand that then listen to the rest of your pitch and you would not have a consulting or salaried position in our workforce. If you choose to use the “It was just an example” defense then understand that professional upper level managers know this and expect the presentation to account for it.

You may be right, but I’m not applying for work as a consultant with the company. I’m interviewing a middle manager for a case study. So that number (whatever it might be) comes from the interview subject, not me. What number would you suggest? I can change that in the article, no biggie.